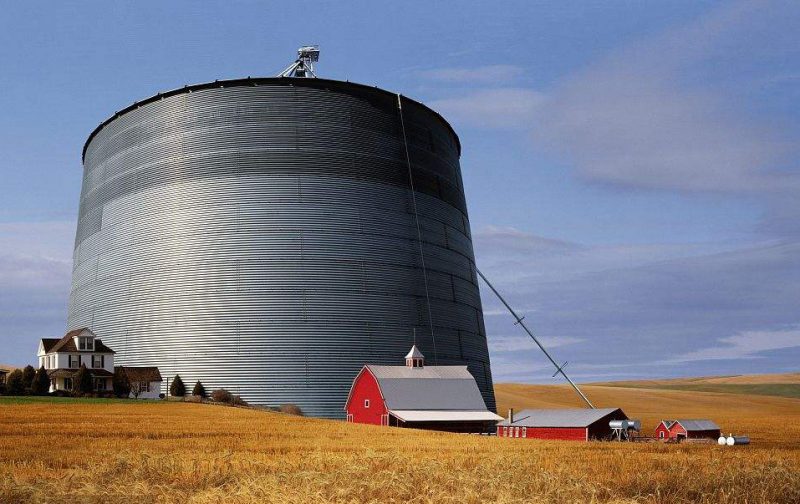

Grain silo is widely used in the grain industry. You can find them in many grain and oil processing plants and grain and oil sales companies.

The capacities of grain silo should be determined by the quantity and variety of grain. There are many factors we should take into account when choosing a grain silo.

How to Decide the Capacity of the Grain Silo?

For large grain and oil processing plants with output of more than 2000 tons, we usually need to build grain silos with capacity of 50,000-80,000 tons. For soybean processing enterprises, because of the simplicity of soybean varieties, enterprises can consider building grain silos with capacity of 10,000-15,000 tons, which is more economical.

For large-scale deep processing enterprises such as corn and starch processing, it is also recommended to choose such large silos because of their large daily processing capacity.

Medium-sized grain and oil processing plants and corn processing enterprises can choose a single steel silo with a storage capacity of about 5000-7500 tons.

For flour processing enterprises, the same standard as grain and oil processing plants can be used to select wheat storage silos, and the capacity of wheat silos should be determined according to daily output. Different from soybean, wheat varieties are more abundant. In order to store different varieties of wheat separately, several steel silos should be constructed. The capacity of a single steel silo is preferably 1000-2000 tons.

For malt and beer processing industry, the capacity of single storage silo should be between 1000 tons and 1500 tons.

For feed processing industry, a single storage silo with capacity between 1000tons and 3000tons is appropriate.

In the field of rice processing, the storage capacity of most rice storage silos is more than 1000 tons.

Small silos installed in trucks for grain transportation are usually hopper bottom silos with small diameters and no more than 500 tons of volume, so that vehicles can directly load grain under the steel silos.

For grain ports and terminals. As a transit point for grain, grain ports have short transportation cycle and large capacity. At present, the storage capacity of China’s coastal ports is mostly 2 million tons, with a single silo capacity between 5000 and 15000 tons.

How to Choose a Proper Grain Silo?

Choosing the right silos is the primary task of grain storage. Our steel silos have the functions of moisture-proof, pest control and rodent control, and is convenient for the input and output of grain. The silo is very airtight and therefore suitable for use with pesticides.

Flyer offers a wide range of galvanized steel silos for grain storage, and provides complete storage solutions and installation equipment for agricultural markets all over the world. Through decades of experience in the design and construction of steel silos, Flyer grain storage silos provide commercial users with the best built-in value in the product life cycle.

Our experienced team of engineers will provide you with professional design from loading, storage to unloading according to your specific requirements. Moreover, all our designs, including preliminary design and architectural design, are free.

In short, the determination of the diameter and height of grain silos and the method of input and output need to take into account many factors. Finally, silos must match the functions you need, otherwise you will not be able to maximize your economic benefits.